Act With Professionalism

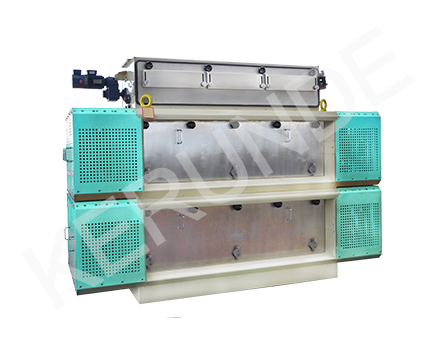

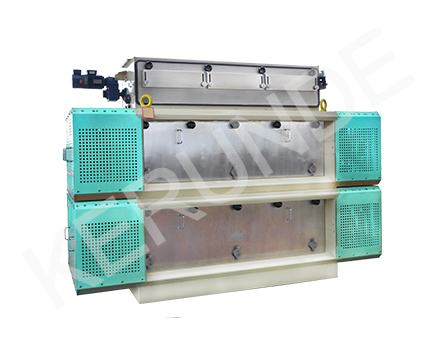

◆ Special roll gap adjustment mechanism enables synchronic adjustment of both ends and/or individual adjustment of either end and eliminates the common problem of interference between rolls during roll adjustment.

◆ Rail type bearing housing facilitating dismantling and positioning of rolls and all other component parts.

◆ Movable PTFE wear-resistant shield positioned on both sides of the working chamber prevents dust emission and material leakage thereby ensuring hygienic working environment.

◆ One-motor-two-wheels driving design ensures precision in roll speed differential setting, increases belt angle, and improves driving efficiency.

◆ Spring-type automatic belt tensioning mechanism.

◆ Heavy duty magnet at feeding point that moves with feeding gate and thus keeps parallel with material stream efficiently picks up iron contained in material stream and effectively protects the rolls.

◆ Flexible configuration: one working chamber with two pair of rollers, one working chamber with one pair of rollers, two working chambers with one pair of rollers each, and three working chambers with one pair of rollers each.

| Model | Capacity(t/d) | Main power(kw) | Feeding power(kw) |

| MPSG30x180 | 800 | 75 | 0.75 |

| MPSG35x180 | 1000 | 1x45/2x45/3x45 | 1.1 |

| MPSG40x210 | 1500 | 1x45/2x45/3x45 | 1.1 |