Act With Professionalism

◆ Wide material adaptability

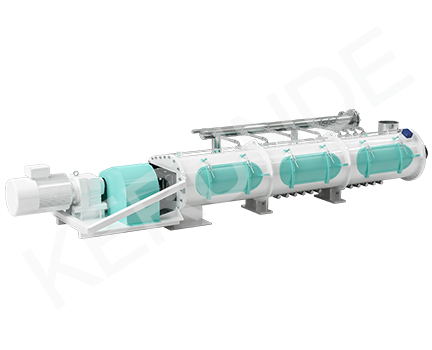

This conditioner serves the functions of high-temperature sterilization, starch gelatinization and protein texturization of various compound feed during conditioning. It provides an efficient pretreatment for pelleting or extrusion and help to improve feed utilization.

◆ Flexible adjustment of parameters

Parameters such as temperature, moisture content and retention time can be adjusted freely and properly to satisfy the different requirements of materials or processes.

◆ Uniform discharge and little residue

With special rotor and barrel structure, the conditioner can facilitate material flow in it and achieve uniform discharge, which contributes to even load distributed on pellet mill or extruder, bringing in stable running, little current change, reduced vibration and noise.

◆ Long conditioning time, uniform liquid addition, high capacity, low noise and convenient assembly.

| Model | Capacity(t/h) | Power(kw) |

| TZSC10 | 0.1-0.25 | 3 |

| TZSC28 | 7.0-12.0 | 15 |

| TZSC33 | 9.0-18.0 | 18.5 |

| TZSC39 | 10.0-25.0 | 22 |

| TZSC45 | 15.0-35.0 | 30 |